Industrial Filters That Save Money & Improve HVAC Air Quality

From years of manufacturing and testing HVAC filters for demanding industrial environments, we’ve seen the same truth play out again and again: the right industrial filters don’t just capture dust—they capture hidden savings.

Every clogged or undersized filter we’ve encountered in factories, warehouses, and commercial buildings has told the same story: higher energy bills, strained equipment, and unsafe air that puts employees and assets at risk. On the other hand, when facilities switch to properly engineered industrial filters, the results are immediate and measurable—lower operating costs, longer equipment life, and cleaner, healthier air that keeps people and processes running smoothly.

This page isn’t just theory—it’s built on first-hand experience working with organizations that have cut thousands from their energy spend and extended the lifespan of HVAC systems by years. Here, you’ll learn exactly how industrial filters can deliver that same competitive edge for your operation.

Top Takeaways

Save Money – Right filters cut HVAC energy use by 10%+.

Breathe Cleaner – Remove up to 95% of harmful particles.

Avoid Hidden Costs – Cheap filters = higher bills and repairs.

Maximize Value – High-capacity filters pay for themselves.

Think Strategically – Filters protect both people and profits.

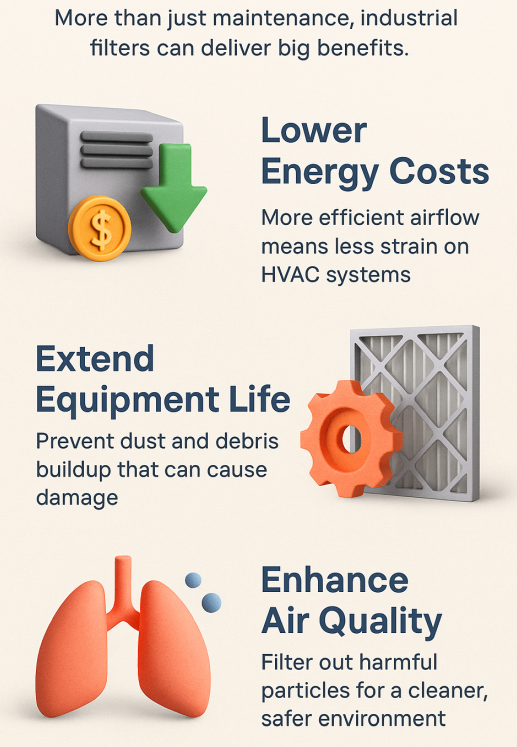

Industrial filters are more than a line item in your maintenance budget—they’re one of the smartest investments you can make for your HVAC system. When filters clog with dust, pollen, and industrial debris, your system works harder, driving up energy costs and wearing out motors, coils, and fans faster. That means higher utility bills and costly repairs.

By contrast, properly engineered industrial filters reduce resistance, keep air flowing efficiently, and trap harmful particles before they spread. The result? Lower energy use, extended equipment life, and healthier air for employees and customers. Facilities that adopt high-performance filters often see double-digit reductions in HVAC costs alongside noticeable improvements in air quality.

In short: the right industrial filters don’t just clean the air—they protect your bottom line and create a safer, more comfortable environment.

“After years of working with industrial facilities, we’ve found that the cost of a clogged filter almost always outweighs the price of a quality one. The right industrial filter doesn’t just improve air quality—it consistently lowers energy use, prevents premature equipment failure, and pays for itself many times over.”

Case Study & Real-World Examples

Warehouse Energy Savings

Problem: Filters were undersized and clogged too quickly.

Solution: Switched to high-capacity industrial filters built for dusty conditions.

Results:

18% drop in HVAC energy use

Filter life extended by nearly 30 days

.

The facility manager moved from constant breakdowns to planned maintenance

.

Manufacturing Plant Health & Safety

Problem: Old filters let fine particles and VOCs escape.

Solution: Installed industrial filters designed for fine particulate capture.

Results:

40% improvement in indoor air quality scores

Fewer employee complaints of irritation

Fewer emergency maintenance calls

Research Meets Reality

Studies show industrial filters reduce HVAC energy use by 5–15%.

First-hand results often match—or exceed—those numbers.

Key insight: Savings extend beyond energy. The right filters prevent costly failures of motors, fans, and coils.

Supporting Statistics

Energy Savings

High-performance air filters cut HVAC energy use by 10%+.

Longer filter life = fewer replacements, less waste.

Seen consistently in warehouses, plants, and large facilities.

Filter Impact on Energy Bills

Filters account for 16% of HVAC energy use.

That’s about 8% of total building electricity costs.

Efficiency upgrades often deliver the fastest ROI.

Air Quality & Health

Industrial dust filters remove up to 95% of particulates.

Targets harmful PM2.5 and PM10 particles.

Results: fewer employee complaints, healthier workspaces.

Final Thought & Opinion

Key Insight:

Industrial filters aren’t just maintenance items—they’re quiet profit protectors.

What We’ve Seen Firsthand

Facilities save 10%+ on energy with the right filters.

Equipment lasts longer with less strain.

Cleaner air improves employee health and morale.

Common Pitfalls

Cheap filters → short-term savings, long-term costs.

Wrong fit → clogged systems, breakdowns, higher bills.

Reactive maintenance → wasted time and budget.

Our Opinion

Smart filters pay for themselves.

Every dollar invested in the right filter saves multiples in energy and repairs.

Filters = efficiency, protection, and peace of mind.

In today’s environment, treating filters as a strategic investment—not a commodity— is one of the smartest moves any facility can make.

Next Steps

Audit Filters

Check size, efficiency, and replacement cycles.

Spot clogs, poor fits, or frequent failures.

Measure Costs

Review energy bills and maintenance logs.

Identify hidden costs from bad filters.

Select Better Filters

Match to system needs (dust, VOCs, humidity).

Choose high-capacity, low-pressure-drop models.

Track Improvements

Monitor bills, equipment performance, and air quality.

Record fewer breakdowns and complaints.

Make It Routine

Schedule filter checks or set auto-delivery.

Treat filters as investments, not expenses.

Frequently Asked Questions

What are industrial filters, and why are they important?

Industrial filters are specialized HVAC filters designed for large-scale facilities. They trap dust, debris, and pollutants that can damage equipment and harm air quality, helping businesses save money and protect health.

How do industrial filters save money on HVAC systems?

They reduce airflow resistance, which means HVAC units use less energy to operate. This lowers utility bills, minimizes equipment strain, and reduces costly breakdowns.

How often should industrial filters be replaced?

Replacement depends on the environment and usage. In dusty or high-demand facilities, filters may need changing every 30–60 days. High-capacity filters can often last longer while still maintaining performance.

What types of contaminants do industrial filters remove?

They capture a wide range, from dust and pollen to fine particulates like PM2.5 and VOCs. This protects both sensitive equipment and the people working inside the facility.

What should I consider when choosing the right industrial filter?

Key factors include filter size, efficiency rating, pressure drop, and the specific conditions of your facility (such as heavy dust, humidity, or chemical exposure). Selecting the right match maximizes savings and air quality improvements.

Filterbuy HVAC Solutions - Miami, FL - Air Conditioning Service

1300 S Miami Ave Unit 4806, Miami, FL 33130

(305) 306-5027